ON THE INDUSTRIAL HISTORY OF THE UNITED KINGDOM

The Industrial Revolution began in the fields of British farmers. Thanks to new cultivation methods, they were able to increase their yields in the 18th century so that the country's food supply was secured and the noble landowners had capital for investment. Added to this was the income from the rapidly growing trade in slaves and slave-produced goods from British colonies. An efficient capital market already existed: at the end of the 17th century, the stock exchange and the Bank of England had been founded in London. In addition, extensive, easily accessible deposits of the key resources coal and iron ore lay in the soils of Great Britain.

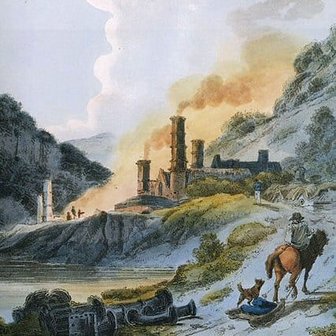

The first pioneering inventions were triggered by a shortage of wood, the main fuel for businesses and households, caused by centuries of deforestation. Probably in 1709, Abraham Darby succeeded in removing unwanted elements from coal in his ironworks in Coalbrookdale near Birmingham. The resulting coke could be used to replace charcoal, the tried and tested but scarce fuel for the blast furnace.

However, a second innovation was needed before the vast coal deposits of central England could be exploited: in 1712, the ironmonger Thomas Newcomen installed the first steam engine in a mine to pump water out of the shafts. This made it possible to reach coal at greater depths – but at the same time, the machine that was to become a universal power unit had been invented.

With the mechanisation of cotton processing, the third key innovation, the textile industry then became the engine of industrialisation. The beginning of this was the “flying weaver’s shuttle” invented by John Kay in 1733. This meant that weavers no longer pulled through the warp threads by hand, but shot them through with the help of a cable. Weaving was thus accelerated to such an extent that innovations in spinning were urgently needed to ensure that enough yarn was available. In 1764, the first spinning machine went into operation: James Hargreaves' "Spinning Jenny", on which 8 yarn spindles rotated, driven by a waterwheel. This was quickly followed by the improved "Waterframe", built by Richard Arkwright, who opened the first factory spinning mill in Cromford near Derby, and finally the "Mule", which carried up to a thousand spindles. A cotton boom broke out when in 1779 Newcomen, and in 1781 his competitor James Watt, succeeded in converting the up-and-down motion of the steam engine into rotation so that it could set tens of thousands of spindles in motion on a single spinning machine. The spinning rooms and dust towers of the "spinning mills" now rapidly multiplied, particularly in Lancashire in Northern England, and Manchester developed as a flourishing centre of trade.

And that was just a prelude. Virtually overnight, Watt's steam engines went into operation in London in a brewery and a flour mill, in a sugar factory in the West Indies and a sawmill in the USA. Soon "Boulton & Watt" from near Birmingham was England's largest engineering company. While Newcomen's original steam engine was used for a long time to raise water in the mines - an example of the not always rapid course of industrialisation - Watt's perfected model also conquered iron processing: it drove the blowers of the blast furnaces so that higher melting temperatures produced better iron and set the heavy rollers in the newly emerging rolling mills in motion, which shaped red-hot iron blocks into sheets, rails and profiles.

The Industrial Revolution in Great Britain was also financed by the trade in slaves and colonial goods produced by slaves – though the extent of this is unclear. Britain had already expanded its overseas possessions in the 17th century; profitable sugar cane plantations had sprung up on the Caribbean islands of Barbados and Jamaica in particular. The more southerly of the North American colonies maintained tobacco plantations, and cotton fabrics came from India. In the 18th century, the trade in slaves from West Africa grew rapidly: British ships transported more than 2.5 million people across the Atlantic to the plantations - more than any other nation. In addition to London, the port cities of Bristol and Liverpool now also became rich. For Liverpool, there is evidence of investment from the proceeds of the slave trade in the nearby northern English coal mines and ironworks, as well as in railway construction and the Welsh slate industry. There were also profits from colonial goods such as sugar, coffee and tobacco, which the ships brought back from America. Besides merchants and bankers, insurance companies and shipbuilding firms, operators of sugar refineries and tobacco factories also profited from this. In 1807, Britiain was one of the first nations to ban the slave trade. The navy sought to enforce the ban worldwide to reduce disadvantages for the British economy.

An important advance in iron smelting was achieved in 1766 by the entrepreneur Henry Cort: his workers had to constantly stir ("to puddle") the pig iron on an open hearth, the "puddling furnace", so that unwanted trace elements and slag could be removed and forgeable steel was produced. Now steelworks and rolling mills were booming in the coalfields of the Midlands, new steelworks were opened in Sheffield, the traditional centre of knife manufacture, and in Scotland the Carron ironworks became a leading armourer.

Steam power and steel also revolutionised transport: the first steam locomotives, developed by mining engineer Richard Trevithick in 1803, still ran on cast rails in the coal mines of Coalbrookdale. The triumphant advance of the railway then began with more stable rolled rails: in 1825 a train transported coal and passengers for the first time. The locomotive came from the workshop of George Stephenson in Newcastle, who then built the first long-distance line between Manchester and the port of Liverpool: the main artery of the textile industry, through which steadily growing quantities of Indian cotton were imported and finished goods exported. By 1838, the link from Birmingham, the centre of the English Midlands, to London was in place, and in the "railway mania" that followed, several thousand miles of track had been laid by the middle of the century.

The pioneers of steam-powered shipping came from the USA, but the first iron-hulled steamer was built by the Briton Aaron Manby in 1822. The first scheduled steamship connection with North America was established by Samuel Cunard in Liverpool in 1840, and the first all-iron passenger ship was launched in Bristol shortly afterwards: the "Great Britain", designed by Isambard Kingdom Brunel, one of the most colourful personalities of the era. Around the middle of the 19th century, full industrialisation was achieved when cheap mass production of iron and steel began and mechanisation was completed in the textile industry.

But the faster the wheels of the new industries turned, the greater their hunger for raw materials became - and the more products poured onto the market. Great Britain, the pioneer of industrialisation, was the first nation to be confronted with these new economic conditions, but the Empire, which expanded almost unchallenged after victories over France, was able to satisfy the changed needs of the economy successfully: In the colonies, British companies now acquired raw materials such as tin or rubber instead of sugar or coffee; in return, they sold mass-produced goods made by machines. The best example is one of the key raw materials of the Industrial Revolution: cotton. India, now Britain’s most valuable colony, had exported cotton cloth for centuries, but now Britons bought raw cotton there to keep the spindles of the spinning machines whirring in Lancashire and then sold the finished goods in India - which ruined textile production there. Or they made a triangular deal: with the proceeds of cotton fabrics from domestic production, Britons bought opium in India and used it to pay for the tea in China that their homeland thirsted for. Chinese resistance to drug imports ended in 1860 with defeat by troops of the colonial powers.