ON THE INDUSTRIAL HISTORY OF TURKEY

By the beginning of the 20th century, the once-glorious Ottoman Empire had deteriorated for all practical purposes into an agricultural colony of the West. Due to its crushing foreign debt, its national budget was under the control of European banks. The West dictated import tariffs, so that domestic businesses were unable to compete with European imports – not even the traditional textile manufacturers. The few factories, which mostly produced agricultural products such as flour and sugar, were in foreign hands, as were the railways. And the agricultural sector was still using the inefficient methods of past centuries.

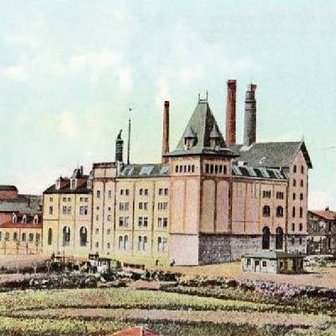

It was only the Turkish Republic, founded in 1923 by Kemal Atatürk, which was able to stimulate the economy, freed from the old constraints. Agricultural yields increased, the infrastructure was nationalised and expanded: in 1924 the government founded the national railway company, which gradually acquired the lines from their foreign owners and ultimately connected the Black Sea coast and eastern Anatolia to its network. Although the first Turkish power station – today the santralistanbul energy museum – was established in Istanbul under the Ottomans, the new era saw the construction of numerous power and hydroelectric plants.

After the Great Depression of 1929, the government pushed the establishment of industry. Following the example of the Soviet Union, the government formulated five-year plans and founded state-owned companies in key industries, which characterised the Turkish economy – with varied success – into the 21st century. This was the impetus behind e.g. Sümerbank, which began expanding textile production in 1935 with an initial factory in Kayseri

However, it was the more liberal economic policies following the Second World War which truly established industrialisation. Initially, the government subsidised food processing and created state-owned operations for cement, fertiliser and chemicals in a bid to become independent of imports. The giant steel works in Ereğli on the Black Sea commenced operation in 1965.

Among the increasing number of private start-ups was the first bakery of sweets manufacturer Ülker in 1944, today a global business. Ömer Sabancı, originally a cotton picker, founded what is today a major family-owned corporation in 1954 with a textile factory in Adana. However, the largest family-owned Turkish company was launched by Vehbi Koç, who in 1959 founded Otosan in Istanbul to manufacture Ford cars under license. Just a few years later, it was followed by Tofaş, which produced Fiats. At the end of the sixties, the powerful Oyak Group, which is owned by the pension fund of the Turkish military, constituted the third pillar of the Turkish automotive industry with the licensed manufacture of Renaults.

However, the crisis-prone economy was unable to establish a strong foundation. Industrial areas emerged primarily in the north-western region of the country and along the Mediterranean coast, which caused a deep divide with respect to the agricultural regions, particularly as the overdue modernisation of agriculture failed to materialise. Additionally, the government protected the new enterprises from foreign competition with subsidies and import tariffs; as a consequence, productivity remained low and very few goods were exported. Foreign debt again grew dramatically, and when the cost of oil imports increased drastically in the 1973 Oil Crisis, Turkey was facing bankruptcy.

Turgut Özal, later Premier and President, is considered the architect of the turnaround after 1980. He implemented a painful austerity policy with wage and price controls, cut subsidies and reduced state influence in the economy. Over the course of the 1980s, exports increased substantially and the country’s notorious trade deficit was brought somewhat under control. High foreign investments, the customs union agreed to in 1996 and the accession negotiations with the European Union served to solidify industrial growth and broaden the range of products.

Today, in addition to textiles, Turkey also exports high-value technical goods, from LCD televisions and household appliances to automotive parts and complete buses. Since the millennium, some of the less-efficient state-owned companies have been privatised: for example Sümerbank, shares in the steel works in Ereğli, and the Tüpraş Group, which controls Turkey’s oil refineries. The food industry contributes significantly to foreign trade with grain, fruit and vegetable products, olive oil and tobacco. Although there is still a great gap between modern agricultural enterprises and small farmers, the country is now independent of food imports.