ON THE HISTORY OF INDUSTRIAL ARCHITECTURE

Two ever-improving materials radically changed construction during the Industrial Revolution: iron, the key material, and concrete. Iron constructions were used to reduce the risk of fire in the British textile industry from around 1800. In a flax mill in Shrewsbury, for example, the architect Charles Bage combined cast-iron columns and T-beams with load-bearing masonry. In a fish market in London in 1835, the iron skeleton took over the load-bearing function alone for the first time, here for hygienic reasons.

The light-flooded buildings constructed almost entirely of iron and glass then had a revolutionary effect: The first was a palm house in the London district of Kew, followed in 1851 by Joseph Paxton's legendary "Crystal Palace" for the Great Exhibition in London. Paxton used prefabricated glass panes and iron or wooden beams, thus anticipating the standardisation that became the norm in the industrialised construction of the 20th century. After that, other halls made of iron and glass were built for exhibitions and also for railway stations - for example, London's St. Pancras terminus in 1873.

The most famous symbol of the time, however, is the iron tower built by the engineer Gustave Eiffel in 1889 for the World's Fair in Paris. Engineers gained increasing influence in the building industry alongside architects, who as well as employing their artistic skills, also understood well the new materials, cost calculation and technical equipment, especially for factory buildings.

Iron constructions were further developed when it became apparent that they were not fireproof, but melted at high temperatures. They were now encased in bricks or tiles, and when safe lifts were developed in 1852, these iron skeletons formed the load-bearing core of the first skyscrapers that rose into the sky, especially in Chicago for insurance company offices.

New possibilities for building with concrete were opened up by Portland cement, a highly efficient new binder developed in 1824 by the British Joseph Aspdin. The decisive factor, however, was the combination of concrete with steel. The French gardener Joseph Monier had the idea in 1867: he used it to make plant tubs. The groundbreaking potential was recognised by his compatriot François Hennebique: thanks to the combination of steel rods or steel meshes, which absorb tensile forces, with a shell of concrete, which absorbs compressive forces, enormous, freely supporting structures can be built from this material.

From the beginning of the 20th century, large domed halls and skyscrapers were built from reinforced concrete: the first European skyscraper was erected by the Royal Liver Insurance Company in 1909 in the port of Liverpool. The next step was taken in the 1920s by the engineer Eugène Freyssinet: he had the steel cables tensioned before they were encased in concrete. ”Prestressed concrete" proved to be less prone to cracking and more resilient, but did not experience its great breakthrough until after 1945.

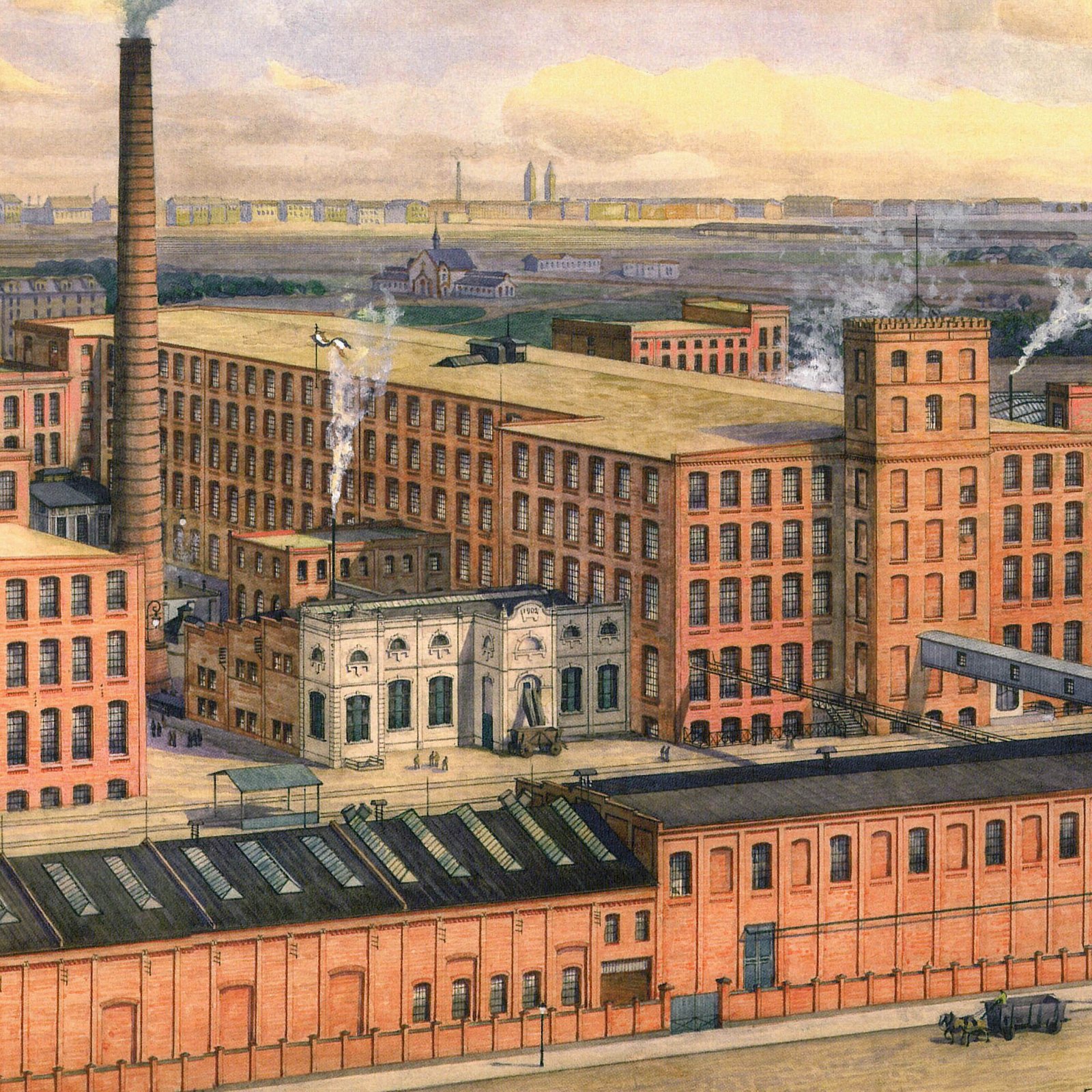

With the increasing mechanisation of construction, tension between engineers and architects came to a head. With "historicism", master builders and clients countered the functionality rejected as "radical abstraction" with stylistic forms from past eras. They used the functional and inexpensive materials of iron and concrete, but clad the outside of their buildings with ashlars or bricks. The administrative buildings of countless factories of this period also have round-arched windows, corner towers and façades richly ornamented with multi-coloured bricks.

The dichotomy also becomes clear in the designs of the respected French architect Eugène-Emmanuel Viollet-Le-Duc, who revived Gothic construction principles with modern materials. Representatives of the British "Arts and Crafts" movement also advocated quality craftsmanship, but could not avoid industrial mass products. And the curved, organic forms of the "Art Nouveau" - in Germany "Jugendstil" - which was widespread throughout Europe, were readily realised in iron and glass - even in industrial construction, as the portal to the machine hall of the Zollern collieries in Dortmund testifies.

After the turn of the century, a group of German architects who gained great influence advocated a well thought-out combination of old and new. The pioneer was Peter Behrens, artistic advisor to the energy giant AEG. He built the assembly hall of a turbine factory in Berlin out of concrete, steel and glass: functionally conceived as a long, column-free hall with windows all the way up to the roof, yet presented in a tradition-conscious way, above all through the use of mighty pillars at the corners of the façade. Although they appear to be structural, , the pillars consist of a thin concrete skin with a steel grid reinforcement and have no load-bearing function.

Innovative functionality and spectacular presentation are also combined in the expressionist hat factory in Luckenwalde near Berlin, which Erich Mendelsohn designed: the concrete building composed of clear geometric elements is accentuated by a towering central section for the innovative exhaust air shafts. Mendelsohn also became famous for department store buildings with elegant curved window bands.

An iconic industrial building was created in 1911 by Walter Gropius, formerly an employee of Behrens, at the "Fagus-Werke" in Alfeld. The 1903 teddy bear factory of the Steiff Company in Giengen near Ulm can be regarded as a forerunner of that building as in front of its load-bearing structure hangs a double-shell wall of iron and glass. For the Alfeld factory, Gropius designed a continuously transparent façade made of windows in thin iron frames and unmistakably demonstrated the construction principle at the corners: they consist entirely of windows, without corner pillars, because the load-bearing supports have been relocated to the inside of the building. The "curtain wall", the curtain-like window façade made of mass produced elements, later developed into a defining architectural feature of the 20th century, especially in high-rise office buildings.

The most radical solution for industrial construction was found in the USA: Ground-level halls took the place of multi-storey large buildings. In 1927, Albert Kahn completed the first large-scale plant in Dearborn near Detroit for the Ford factories, which were the first to consistently use assembly line work: a huge hall made of prefabricated steel modules, erected quickly and cheaply, in which the cars went through all the production steps one after the other. If the production process is to be changed or the plant enlarged, steel modules can be converted more quickly than a concrete structure, which requires formwork and drying time. The steel skeleton construction thus perfectly fulfils the requirements of capitalist industrial production, which must always be technically and economically variable.